Internal Inspection

- Home

- Our Services

- Inspection

- Blade Internal Inspection

Technology

Blade Internal Inspection

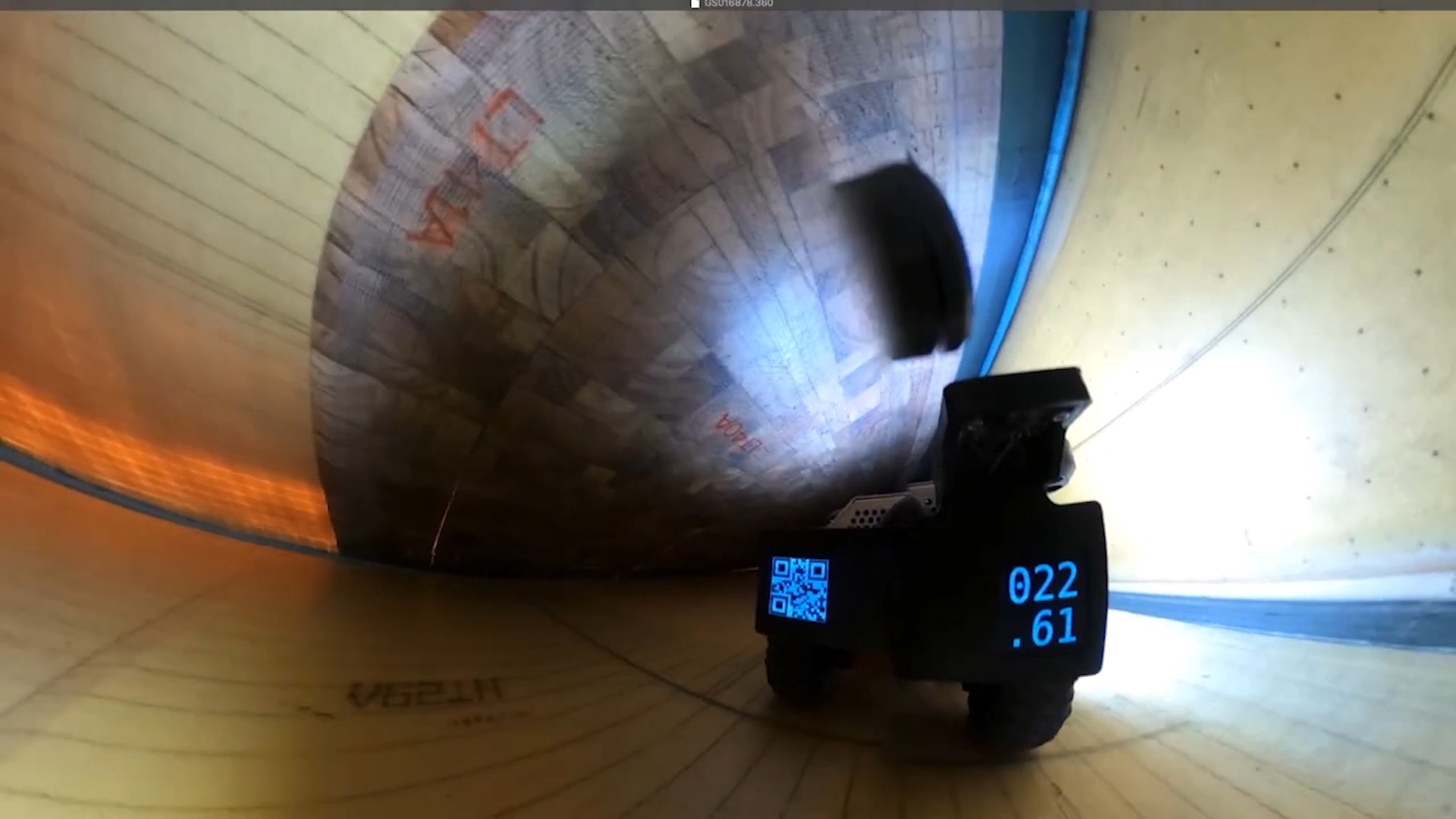

We have designed a dedicated crawler for high-quality internal inspections, allowing us to expand the reach and coverage existing methodology for internal inspections can offer. Due to the crawler's small size, we are capable to perform internal inspections on the majority of blades on active wind turbines - where it was previously impossible via manual approach. Additionally, our crawler-bot is equipped with powerful lights and HD 360-degree view cameras able to capture the full internal area of the turbine blade.

01

Deeper access

Reach up to 80% inside the blade to find hidden damages

02

HD 360 inspection footage

Detailed, steady and well-lit video of blade inspection with location mapping

03

LIDAR measuring

Measure and track the progression of damages with LIDAR point cloud measuring

04

Advanced reporting

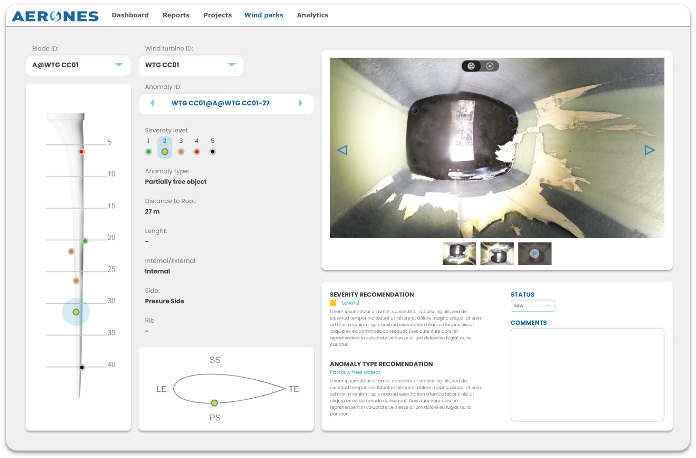

Receive professional reports in our platform for deep analysis

01

Deeper access

Reach up to 80% inside the blade to find hidden damages

02

HD 360 inspection footage

Detailed, steady and well-lit video of blade inspection with location mapping

Inspection process

Aerones technicians operate the crawler to record the data which is reviewed and processed by in-house data analysts in a timely manner

Monitor damage progression

Often the internal condition of the blade can differ completely from the external condition, leading to overlooked significant damages of the blades that can cause high-cost repairs (and unearned profits), if not treated in a timely manner.

Review wind park inspection results with image and video data. Map the anomalies and know the precise location. Review recommendation and save comments for further analysis work.

Digital data platform

Cloud platform gathers unique cross-industry dataset from inspections which enables pricing of smarter preventive maintenance plans & budgets

Contact us

Schedule a presentation, receive a detailed information about the services or request a price quote

Contacts

EU: Vestienas 32, Riga,

Latvia, LV-1035,

US: 105 N 1st St #429 PMB 22980

San Jose, CA 95103

Phone: +371 2809 0999

Phone: +1 669 213 80 50

Email: [email protected]