Avoid Costly Wind Turbine Downtime

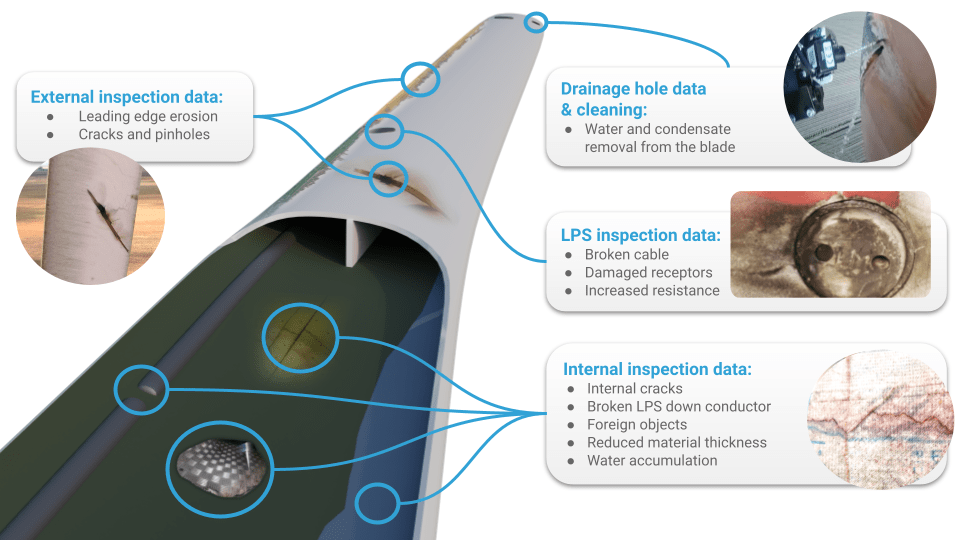

Wind turbines need to be inspected and monitored regularly to ensure they are operating efficiently and avoid any unwanted damage. Turbine downtime can occur due to lightning damage, unnoticed blade cracks, erosion, or total blade destruction.

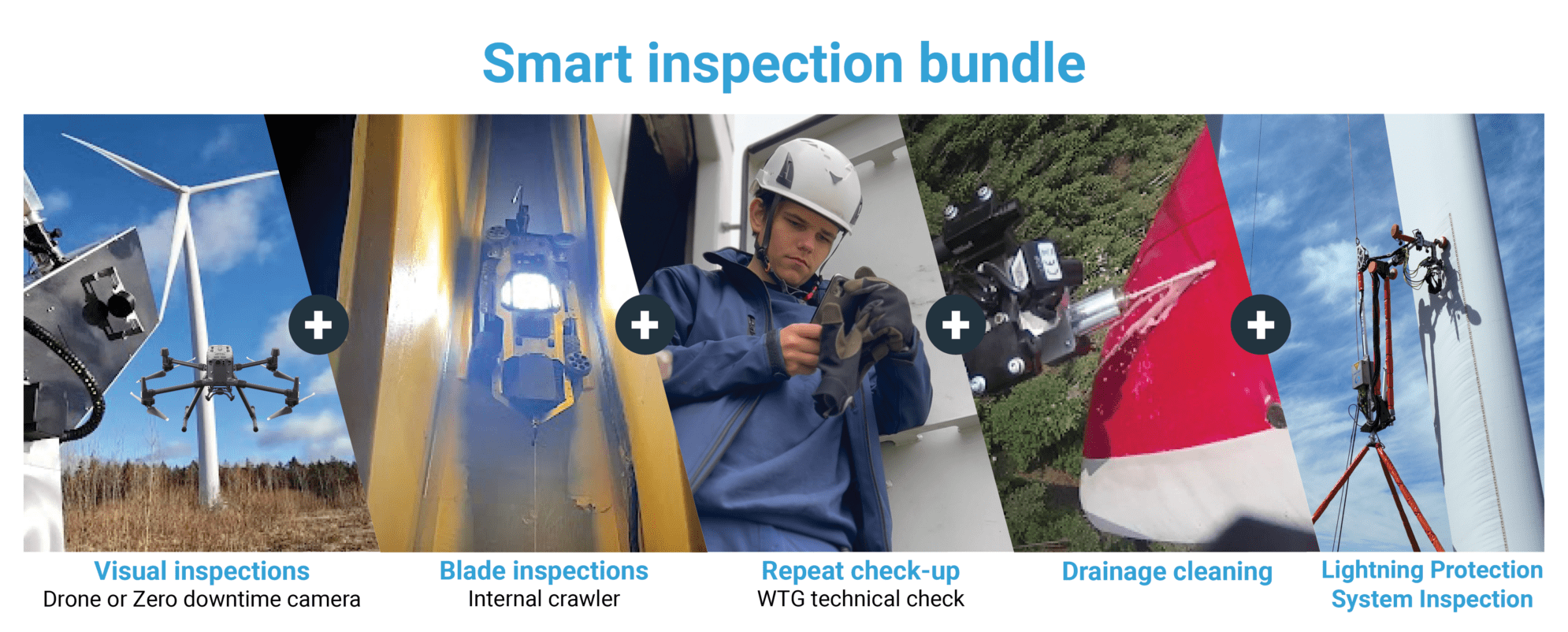

Aerones offers a large range of inspection services for onshore and offshore wind turbines all around the world.

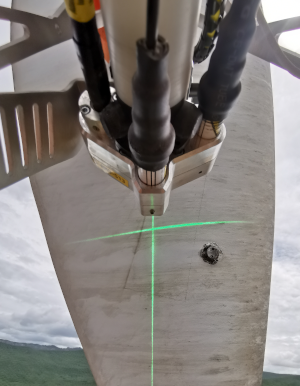

The robotic systems provide objective and independent information on the condition of the LPS system, blade internal and external health, the quality of blade repairs, and water accumulation inside the tip of the blade.

Robotic tools help you reduce risks, avoid damage, reassure stakeholders, and meet regulations while significantly minimizing downtime.

Inspection results are stored in our client portal and can be further analyzed by specialists. Our tools are certified and our technicians are fully trained on all relevant safety, measurement and operational topics. Our robots are more durable than humans, allowing them to work in a wide range of locations and weather conditions, reducing idle-stay days.